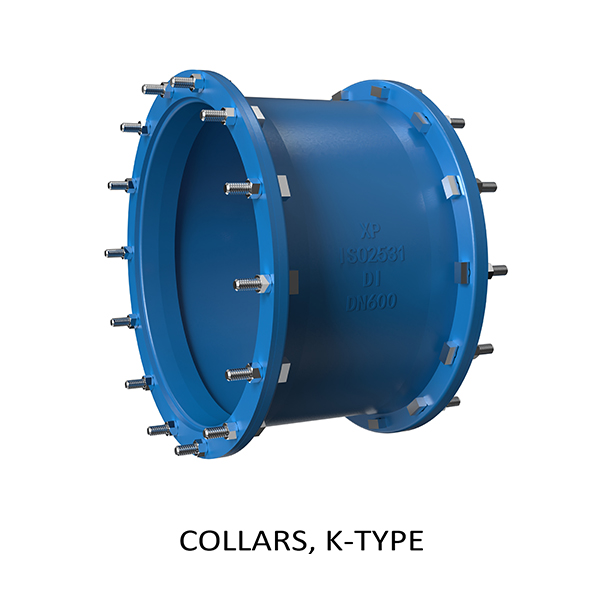

Fitting

ISO2531/EN545/EN598

General Specifications

DUCTILE IRON ISO2531/EN545/EN598

Conforming Standards:

ISO 2531

Ductile Iron pipes, fittings, accessories and their joints for water applications.

BS EN 545

Ductile Iron pipes, fittings, accessories and their joints for water pipelines-requirements and test methods.

BS EN 598

Ductile Iron pipes, fittings, accessories and their joints for sewerage application

requirements and test methods.

Size Range:

80mm-3300mm(Fittings & Dimnsions Available On Request)

Joints:

Push-On Joint (TJ)

The push-on joints are most jointing system with high reliability. Push-on joints are assembled with synthetic rubber gaskets which gets compressed when the spigot is inserted into the socket. The joints become tighter with the increase in internal pressure of water. It is an easy to join system which allows rapid low-cost laying even in wet condition.

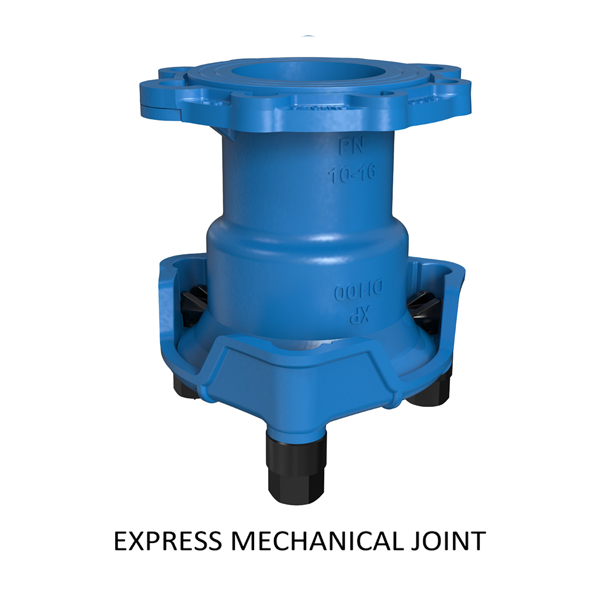

Mechanical Joint (MJ)

In this kind of flexible joint, sealing is obtained by applying pressure to the gasket by mechanical means, via through a separate gland. When bolted with the pipe, the gland exerts pressure on the sealing rubber gasket and makes the joint leak proof.

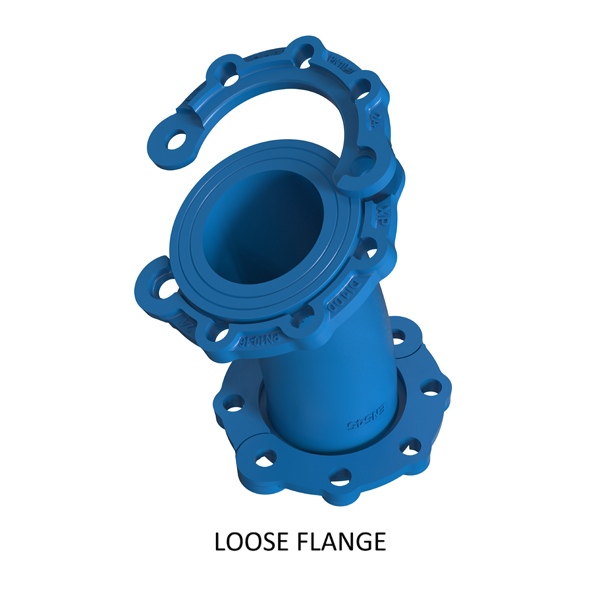

Flange Joint (FJ)

In any pipeline system there are certain lengths, which are exposed and are not buried under the earth. These lengths need to be tied down to pillars to avoid movements. For this kind of application, flanged joints are used. Flanged joints are also used for vertical pipelines and inter connection of utilities.

Restrained Joint (RJ)

Restrained joints are special joints, which can take care of axial thrust. Flexible restrained joints are also used in high slope or where horizontal/vertical ground movement is anticipated. These joints are necessary on fittings and a few pipes adjacent to the fittings. Restrained joints eliminate use of concrete anchor blocks, which are costly and delay the progress of laying.

Blocked Restrained Joint/Positive Locking Joint

The blocked restrained joints, also known as positive locking push-in joints can always be recognized by a welded bead on the spigot end and a retaining chamber. The positive locking interengagement between the welded bead and the retaining chamber is obtained by inserting locking segments. This enables forces to be transmitted mechanically between the spigot end and the socket of the next pipe or fitting.

Type of Linings:

Ordinary Portland Cement (OPC)

High Alumina Cement (HAC)

Sulfate Resistant Cement (SRC)

Blue/Black/Red Epoxy Seal Coat

Type of Coatings:

Rich Zn & Zn-Al Coatings as per International Standard

Finishing Layer:

Blue/Black/Red Epoxy or Black Bitumen

Anti-Corrosion Coating:

The both internal and external Fusion Bonded Epoxy (FBE) coating is an anti-corrosion coating. This coating ensures that the fittings are tough and durable, especially in sour conditions.